The egg tray making machine is an ingenious item of tools made for the production of high-grade egg trays, which are vital for product packaging and carrying eggs securely. As the demand for egg-based items remains to climb, the requirement for efficient and dependable product packaging options becomes critical. Egg tray making equipments provide to this need by offering an automated approach for producing trays that are not only sturdy and lightweight but additionally environmentally friendly. These makers are made to convert raw materials like recycled paper, cardboard, or agricultural waste into pulp and after that mold it into functional egg trays. In a world significantly concentrated on sustainability, this process provides an exceptional possibility for companies wanting to decrease their environmental influence while still meeting market needs.

The egg tray making process starts with the collection of waste or cardboard, which is after that shredded and incorporated with water to develop a pulp. This pulp is an environment-friendly alternative to conventional plastic egg trays, which pose considerable disposal obstacles and add to environmental pollution. The pulp undertakes a refining process, guaranteeing that it accomplishes the right consistency for molding. Once prepared, the pulp is fed right into the egg tray making machine, where it is shaped right into trays making use of mold and mildews that can suit numerous egg dimensions. The automated nature of this machinery ensures that production is both regular and efficient, making it perfect for organizations seeking to scale their operations.

One of the primary advantages of purchasing an egg tray making machine is the considerable price financial savings it provides. Standard egg packaging methods commonly include sourcing and acquiring pre-made plastic trays, which can be pricey and subject to market fluctuations. In contrast, creating trays in-house permits companies to control their manufacturing expenses extra efficiently, as they can source basic materials in your area at a reduced price. Additionally, the capability to reuse waste materials not only reduces the price of basic materials but likewise positions services as eco accountable entities, attracting a growing consumer base that focuses on sustainability.

The convenience of egg tray equipments is an additional significant advantage. These machines can be set up to generate numerous kinds of trays, consisting of those for chicken eggs, quail eggs, and also fruit, depending on the molds used.

Security is likewise a substantial factor to consider in the egg industry, as eggs are delicate products susceptible to damage during transportation and handling. Properly designed egg trays provide the needed protection, cushioning the eggs and reducing the threat of breakage. This vital performance is accomplished many thanks to the unique design of the trays, which features specific clinical depressions to safely hold each egg in position. This layout not just reduces the likelihood of physical damages to the eggs however additionally optimizes storage space and shelving, taking full advantage of room during circulation and retail processes.

Along with the physical benefits of making use of egg trays, there are additionally significant advertising and marketing advantages. Eco-conscious consumers progressively seek products that straighten with their values, and biodegradable product click here packaging is a significant selling factor. By using an egg tray making machine to generate green trays, organizations can properly market their products as sustainable and responsible selections, capitalizing on a fad that shows no indicators of slowing down.

The egg tray making machine operates efficiently, typically needing only a tiny group to look after the manufacturing process. This effectiveness results in lower labor prices, and the machine's automated attributes reduce human error, making certain top quality output with minimal downtime. Modern makers come outfitted with sophisticated innovation, including PLC (Programmable Logic Controller) systems, which supply individuals real-time surveillance of production metrics, thus enhancing functional effectiveness. This high-tech service not just simplifies the manufacturing procedure yet additionally substantially lowers the need for hands-on labor, creating more chances for companies to buy their labor force in various other locations.

One more critical component adding to the popularity of egg tray equipments is the capacity for personalization. Several check here suppliers offer a series of choices that enable companies to tailor their manufacturing lines to fit their specific demands. This personalization can consist of adjustments in manufacturing ability, speed, and also the density of the trays produced. This level of versatility means companies can adapt to market needs extra dynamically, scaling up or down based upon transforming conditions.

The international demand for eggs continues to increase, driven by an increase in intake in arising markets and altering dietary preferences worldwide. Spending in an egg tray making machine currently permits businesses to place themselves advantageously in this advancing market.

Some makers have also integrated energy-efficient devices into their egg tray machines, further boosting their sustainability charm. These equipments can run with minimal energy usage, properly minimizing the carbon footprint linked with egg tray production.

As several business owners and businesses look for to expand their procedures, venturing into egg tray production uses click here a profitable possibility. The investment in an egg tray making machine is supported by the property of tapping into a market with steady demand.

Setting up an egg tray making machine needs careful planning and factor to consider. Companies should take into consideration factors such as the neighborhood accessibility of resources, the target market, and the circulation logistics. Identifying the very best location for the manufacturing unit is also important for making sure a stable supply chain. By selecting to purchase a machine that supplies high efficiency and customization, organizations stand better opportunities of success in the affordable landscape of egg packaging.

Beyond manufacturing, continuous upkeep and assistance are essential components of operating an egg tray making machine. Lots of suppliers bieten substantial consumer solution and technological support, aiding organizations in repairing possible challenges and making the most of machine uptime. Educating programs are also frequently used to ensure that drivers are proficient in utilizing the modern technology efficiently. This commitment to client complete satisfaction aids develop lasting collaborations, cultivating mutual development and success.

Future advancements in egg tray making technology must likewise be taken into consideration when reviewing prospective financial investments. Technologies in machine layout, such as automated stacking systems, are most likely to emerge, further enhancing manufacturing efficiency.

In verdict, the egg tray making machine is a keystone of contemporary egg product packaging solutions, providing substantial benefits in regards to effectiveness, price, and sustainability. As organizations look to enhance their operations and meet the increasing customer demand for eco-friendly products, this innovative machinery offers as a vital property. By converting waste materials right into functional, naturally degradable egg trays, business can straighten their manufacturing procedures with existing global trends and customer habits. Ultimately, the assimilation of an egg tray making machine stands for a calculated financial investment for companies aiming to operate responsibly while guaranteeing earnings in the competitive globe of egg manufacturing and product packaging. As demands progress and the relevance of sustainability remains to climb, engaging with this modern technology ends up being not simply a company choice, but a commitment to cultivating a healthier earth and a much more accountable future for the sector.

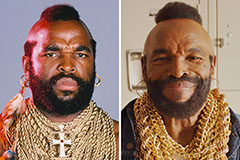

Mr. T Then & Now!

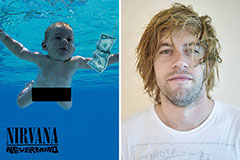

Mr. T Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!